Our Services

Professional Waterproofing Services for Your Building

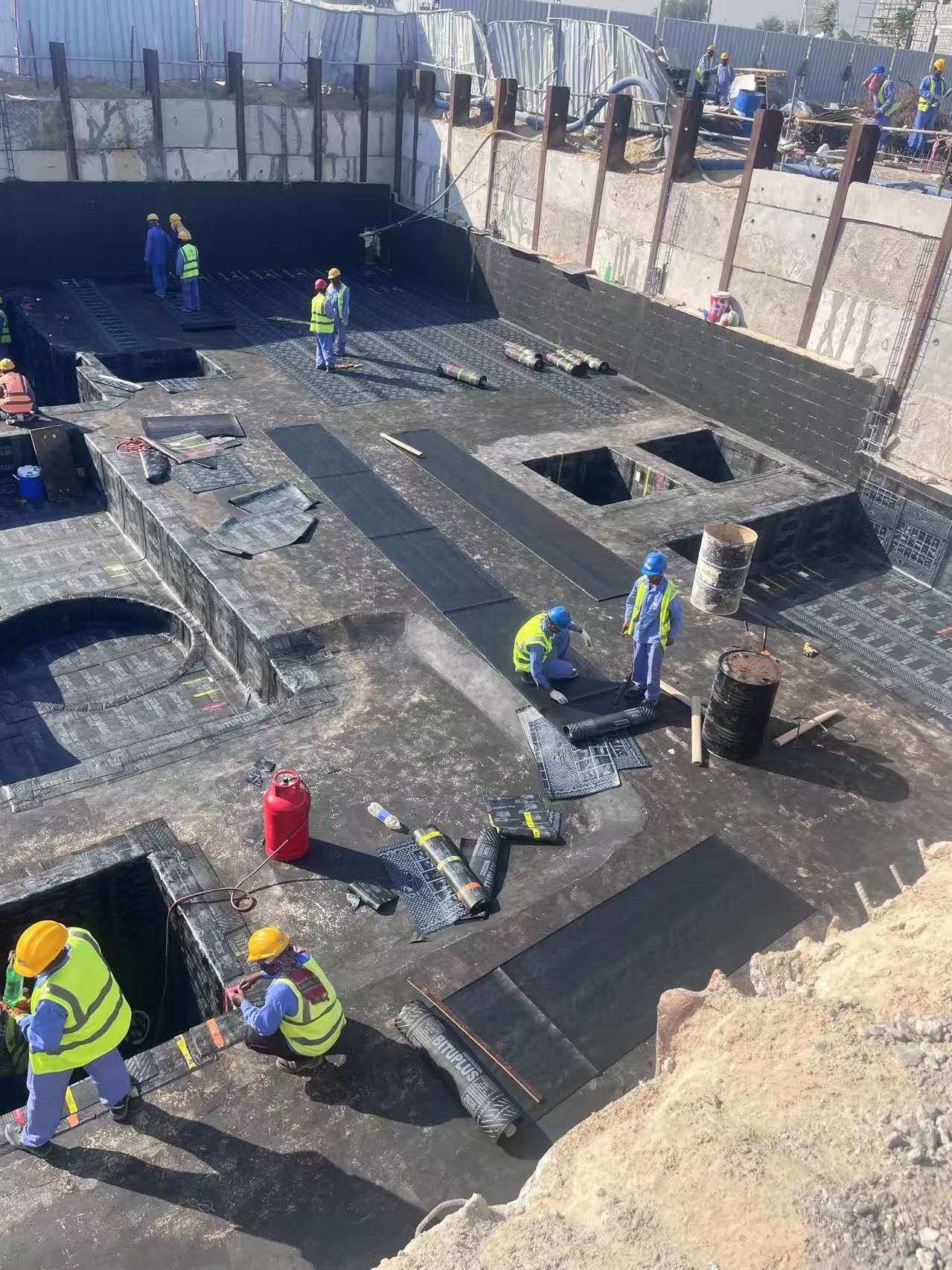

Bituminous Waterproofing Dubai

Bituminous waterproofing systems serve as a protective barrier for both residential and commercial structures. Bitumen, a blend of organic liquids, is highly adhesive, viscous, and inherently waterproof. Bituminous membranes are constructed from a combination of components: bitumen itself, often compounded with limestone, sand, or polymers; base materials such as polyester or fiberglass; mineral granules; and a thin, transparent film.

Bituminous roofing membranes hold a substantial share in today's roofing market, with a robust reputation for reliability. They flex with the building's movement but resist water absorption, offering an extensive lifespan. Many membranes are certified with British Standard marks, ensuring quality and longevity. Their application process generates minimal noise pollution. These membranes shield insulation and can reflect damaging sun rays. Additionally, some newer products integrate photovoltaic cells to generate solar energy.

There are two main types of polymer-modified bitumen membranes: those modified with atactic polypropylene (APP) and those with styrene butadiene styrene (SBS). These polymer-modified membranes exhibit differing characteristics and applications. Generally, atactic polypropylene-modified bitumen exhibits properties akin to 'plasticized asphalt,' whereas styrene butadiene styrene-modified bitumen presents as 'rubberized asphalt.'

Liquid Roofing Dubai

This waterproofing technique is frequently employed in wet environments such as bathrooms, kitchens, toilets, balconies, and laundry rooms. Prior to application, the concrete floor must be thoroughly dry, smooth, and free of any debris. The liquid waterproofing membrane is supplied in a fluid state and can be applied via spraying, brushing, or rolling onto the concrete surface. Upon exposure to air, it cures to form a continuous, joint-free membrane.

A key advantage of this method lies in its application simplicity. The absence of joints significantly reduces the risk of water seepage, a common issue with roll-on sheet waterproofing membranes and other conventional methods. Contractors can efficiently cover large areas in a single day, and subsequent applications can be overlapped seamlessly the following day.

These liquid-applied systems exhibit excellent elongation properties, durability, flexibility, and resistance to abrasion and chemicals, ensuring a successful installation. The liquid waterproofing membrane offers optimal performance and exceptional longevity. Additionally, this method is time-efficient, allowing other construction activities to continue uninterrupted, as the membrane dries and strengthens swiftly, typically from morning to afternoon. This not only reduces labor costs but also delivers high-quality results.

Damp Proofing Dubai

Damp-proofing in construction refers to moisture-control measures applied to walls and floors to block moisture intrusion into interior spaces. Damp issues rank among the most common residential challenges. A Damp-Proof Course (DPC)—a horizontal barrier in walls—prevents capillary moisture migration (rising damp) by interrupting water wicking through masonry. Similarly, a Damp-Proof Membrane (DPM) safeguards solid floors from ground moisture. Simply put, DPC halts dampness in structures. Installed at the plinth level (where walls meet foundations), DPC creates an impermeable layer to stop moisture from reaching interior walls.

Foam Concrete

Foamed concrete stands out as a remarkably versatile material, characterized by its ease of workability and low density, thanks to its composition which can include up to 50% entrained air. This material possesses self-leveling and self-compacting qualities, making it convenient for pumping applications. Ideally suited for filling voids, foamed concrete excels in addressing challenging spaces such as decommissioned fuel tanks, complex sewer networks, pipelines, and culverts. Its excellent thermal insulation properties further enhance its suitability for use in sub-screeds and filling underneath floor cavities.

Resembling aerated concrete, foamed concrete belongs to the category of porous concretes. Its creation involves the even dispersal of air bubbles within the concrete mass, resulting in a unique structure. In roofing and flooring applications, foamed concrete serves as an effective heat and sound insulator, commonly employed in multi-level residential and commercial buildings with rigid floors. Additionally, it finds utility in interspace filling between brickwork leaves of underground walls, insulation within hollow blocks, and the fabrication of precast blocks, curtain walls, partition panels, and slabs for false ceilings. Its combination of superior insulation and lightweight properties makes it an ideal choice for roofing systems.

GRP Lining

GRP Foam Lining stands as a remarkable breakthrough in the fiberglass domain, offering an array of benefits that span from corrosion resistance to structural enhancement and waterproofing capabilities. This lining finds its place in a vast range of applications, including water storage tanks, sewage containers, chemical repositories, tank roof linings, access manholes, sewage pits, cooling towers, chemical plants, firefighting systems, pipeline networks, and water transmission pipelines, to name a few.

The use of specially formulated resins equips the GRP Lining with exceptional qualities, allowing it to endure exposure to fungi, algae, harsh acids, chemicals, and elevated temperatures. As a result, it serves as a highly effective and efficient alternative to component replacement, seamlessly sealing cracks, leaks, corrosion, and flaking materials.

Moreover, GRP Lining revitalizes damaged or eroded surfaces, extending the lifespan of structures and providing a long-term, secure environment. This is achieved at a fraction of the cost associated with complete reconstruction, making it a cost-effective solution that preserves the structural integrity of affected areas while ensuring reliable and sustained performance. In conclusion, GRP Lining not only addresses immediate repair needs but also contributes to significant cost savings and enhanced operational efficiency over the long term.

Combo Roofing System

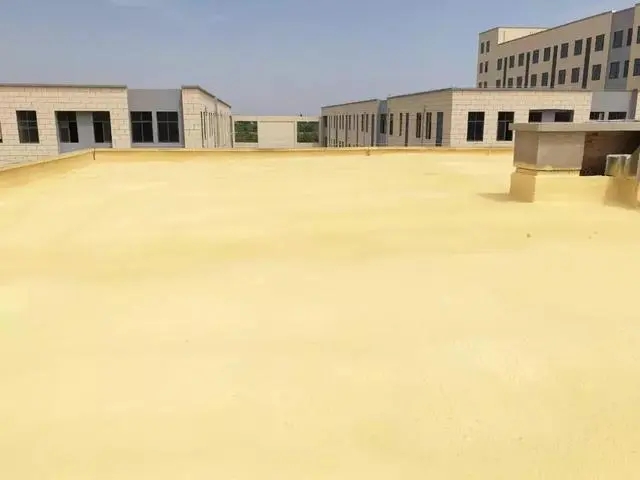

The lifespan of a building heavily relies on the quality and durability of its roof. For a roof to function effectively over time, three key factors are crucial: the quality of the materials used, the design of the roofing system, and the skill of the workmen. Given the extreme heat in the Middle East, superior insulation is vital to prevent energy loss. The DHCN Combo Roofing System excels in this aspect, offering over 40% energy savings. Moreover, it provides impeccable waterproofing, making it an ideal and cost-effective solution.

Spray foam roofing begins as two liquid components: Foam/Polyol, known as the "A" component (MDI), and Polyol, the "B" component. When mixed in a one-to-one ratio, a chemical reaction occurs, causing the mixture to expand 20 to 30 times its original volume. This results in a solid, seamless, closed-cell roof system that adheres fully to the surface, providing excellent water resistance and thermal insulation. Using polyurethane foam mechanics, a tapered roof system can be spray-applied, eliminating the need for expensive tapered insulation systems. The vertical wall terminations are also spray-applied, integrating them into the roof system and reducing additional costs.

The Combo Roof is an all-inclusive system that combines waterproofing, thermal insulation, and finishing for the roof. It has received approvals from various authorities such as Dubai Municipality, Sharjah Municipality, Sharjah Water and Electricity Authority, and Trakhees, ensuring it is a reliable choice for your roofing needs. Polyurethane foam adheres to nearly any surface, including concrete and wood, and is trusted by major property developers, consultants, and contractors. The system comes with a manufacturer's guarantee of 25 years against any leakage and meets all the latest thermal insulation standards and regulations in the UAE.

Crack Injection

GRP Foam Crack Injection is an advanced repair method for concrete cracks, both horizontal and vertical. Using the Bore Packer Method, it permanently seals leaky areas like pools and basements, withstanding hydrostatic pressure and dynamic cracking. This flexible and durable solution restores structural integrity. Our specially formulated injections fuse cracks, reinstating concrete's strength. In short, GRP Foam Crack Injection ensures long-term, effective repairs.

Service Process

Site Inspection

Professional engineers conduct on-site assessment

Solution Design

Develop customized solutions based on site conditions

Implementation

Strict execution according to standards

Quality Check

Comprehensive testing to ensure quality